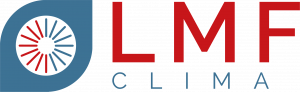

- Supporting frame in extruded aluminium profiles with thermal break

- Sandwich panels th. 42 mm in internally galvanised sheet and pre-painted externally in RAL 9002 finish.

- Non-flammable thermal and acoustic insulation in high insulation mineral wool

- Static heat recovery unit with very high efficiency of the counter flow air-to-air type with aluminium exchange plates fitted with additional sealing, integrated with an already motorised by-pass system. Aluminium condensate collection tank with 1” dual side drain.

- Rigid pocket filters with polystyrene frame with polyurethane seal and medium water-repellent fiberglass. Efficiency class ePM10 70% on room return and ePM1 50% on outdoor air intak e.

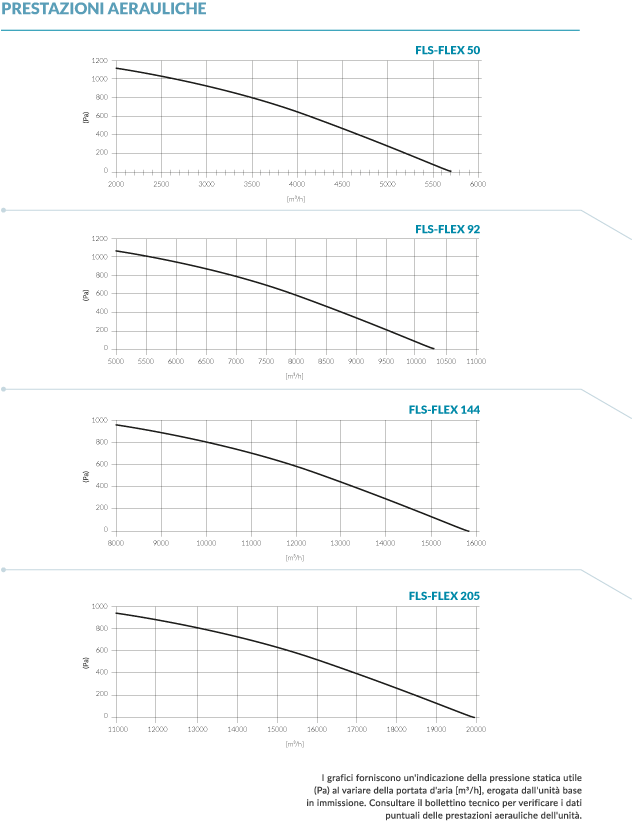

- Centrifugal fans with free-running impeller with backward blades directly coupled to EC technology electric motors.

- Electrical panel complete with remote display and microprocessor to manage the thermoregulation at a fixed point in supply, based on operating logics designed to maximise energy savings and room comfort, by means of airflow modulation guaranteed by inverter technology. The unit is designed for connection via RS485 to supervision systems based on the Modbus RTU protocol.

Very high efficiency heat recovery unit with integrated by-pass

Standard remote control panel

Water dehumidification external section

(1) outdoor air/inlet circuit

(2) at nominal airflow, inlet air 28°C 60% RH, in/out water temperature 7/12°C

(3) at nominal airflow, inlet air 15°C, in/out water temperature 50/44°C

(4) air inlet 29°C 65% RH, in/out cold water temperature 7/12°C, in/out reheating water temperature 40/30°C

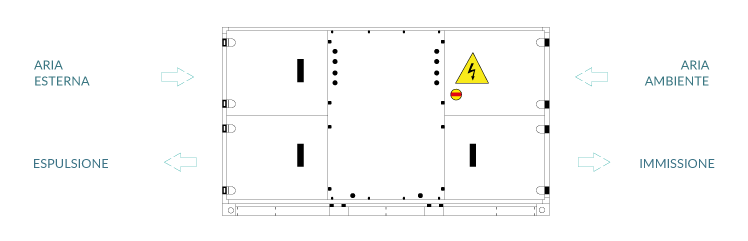

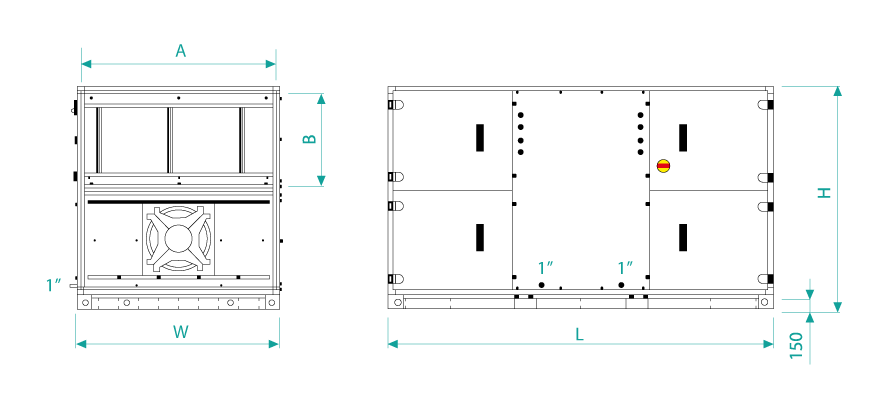

Two air flow configurations are available, a “right” and a “left” one, both referring to the view of the electrical panel and taking into account that the inlet circuit is always located at the lower level:

with the first, the inlet fan is to the right of the electrical panel. The other three aeraulic connections are automatically uniquely defined

with the second, the inlet fan is to the left of the electrical panel. The other three aeraulic connections are automatically uniquely defined

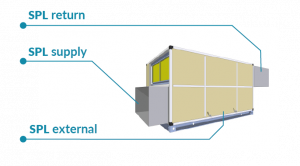

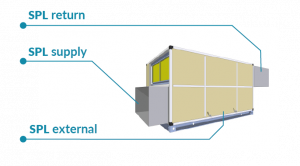

The table shows the sound power values (SWL) in octave and total bands. The sound pressure levels (SPL) at 1m, 5m and 10m in supply, return and outside the unit are also indicated.

All values refer to the operation of the ducted unit at MAXIMUM speed and nominal flow rate.

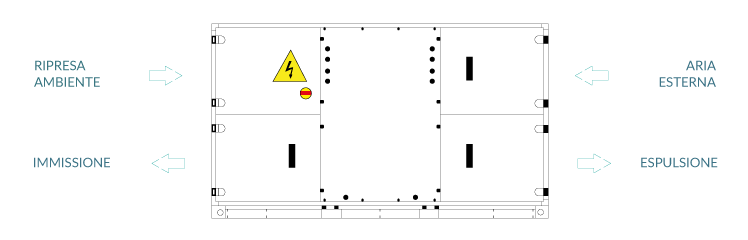

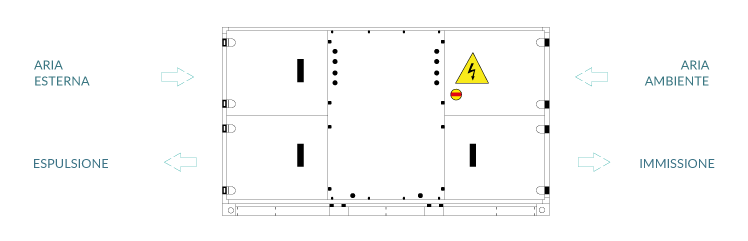

Two air flow configurations are available, a “right” and a “left” one, both referring to the view of the electrical panel and taking into account that the inlet circuit is always located at the lower level:

with the first, the inlet fan is to the right of the electrical panel. The other three aeraulic connections are automatically uniquely defined

Two air flow configurations are available, a “right” and a “left” one, both referring to the view of the electrical panel and taking into account that the inlet circuit is always located at the lower level:

with the first, the inlet fan is to the right of the electrical panel. The other three aeraulic connections are automatically uniquely defined

with the second, the inlet fan is to the left of the electrical panel. The other three aeraulic connections are automatically uniquely defined

with the second, the inlet fan is to the left of the electrical panel. The other three aeraulic connections are automatically uniquely defined

The table shows the sound power values (SWL) in octave and total bands. The sound pressure levels (SPL) at 1m, 5m and 10m in supply, return and outside the unit are also indicated.

All values refer to the operation of the ducted unit at MAXIMUM speed and nominal flow rate.

The table shows the sound power values (SWL) in octave and total bands. The sound pressure levels (SPL) at 1m, 5m and 10m in supply, return and outside the unit are also indicated.

All values refer to the operation of the ducted unit at MAXIMUM speed and nominal flow rate.