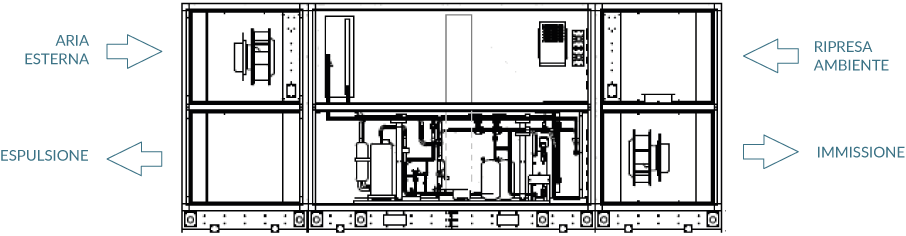

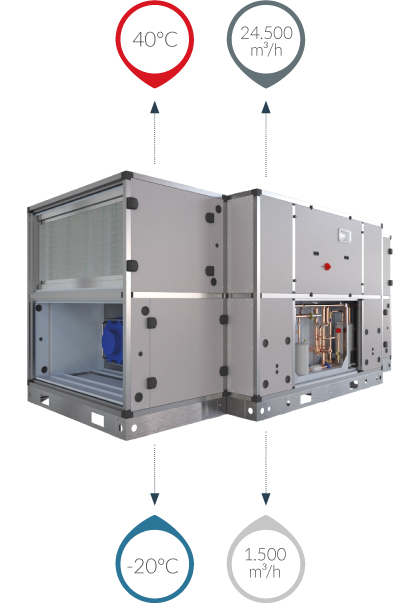

- Supporting structure in extruded aluminium profiles, panels (th. 42 mm), sandwich type, with special sealing gaskets; external finish RAL 9002; thermoacoustic insulation in high density 0 class rockwool.

- Filter sections on recirculation air in efficiency class ISO ePM1 50% and ISO PM10 50% on return air.

- Fan sections with plug fans with backward blades, directly coupled to EC brushless electronic motors.

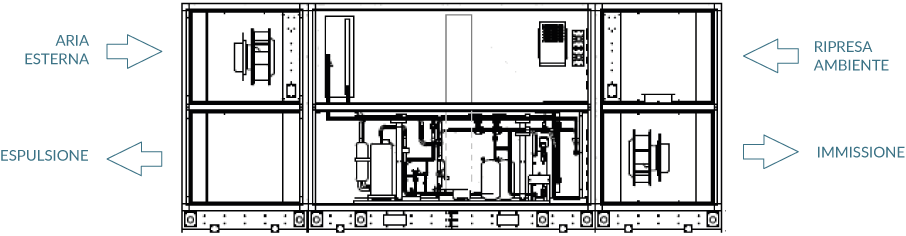

- Storage type heat recovery unit with high efficiency >(> 75%) enthalpy rotor in hygroscopic aluminium with motor with fixed speed gearbox and belt drive.

- Dynamic recovery section created with R410A reversible refrigerant circuit, consisting of: EC twin rotary brushless hermetic compressor(s) with dedicated inverter, Cu/Al finned tube evaporator/condenser, electronic expansion valve, cycle reversing valve, high pressure switch, high and low pressure transducers, liquid separators and receivers.

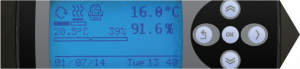

- Electrical panel complete with on-board machine display and microprocessor to manage the fixedpoint thermoregulation in delivery, based on operating logics designed to maximise energy savings and environmental comfort, thanks to the modulation of cooling capacity and air flow guaranteed by the inverter technology. The unit is prepared for connection via RS485 to supervision systems based on Modbus RTU/Modbus RTU/RS 485/Modbus TCP/ IP protocol; Bacnet TCP; Webserver.

Standard electronic control with graphic display

High efficiency enthalpy heat recovery unit

Built-in reversible cooling circuit

(A) Input temperature ≤ 20°C; balanced air flow rates

(B) Input temperature ≥ 22°C; balanced air flow rates

(1) outdoor air at -5° C 80% RH, ambient air at 22°C 50% RH; nominal air flow rate

(2) outdoor air at 32° C 50% RH, ambient air at 26°C 50% RH; nominal air flow rate

(3) with ventilation regulation signals and heat pump at the maximum permissible value

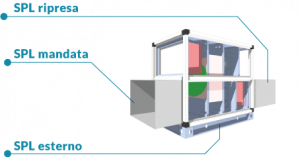

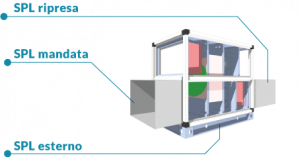

With reference to the nominal operating conditions, the following table shows the sound power values (SWL) in octave band and the related results; the sound pressure values (SPL) at 1m, 5m and 10m in supply, in return and outside of the unit are also highlighted, under ducted unit conditions.

table shows the sound power values (SWL) in octave band and the related results; the sound pressure values (SPL) at 1m, 5m and 10m in supply, in return and outside of the unit are also highlighted, under ducted unit conditions.

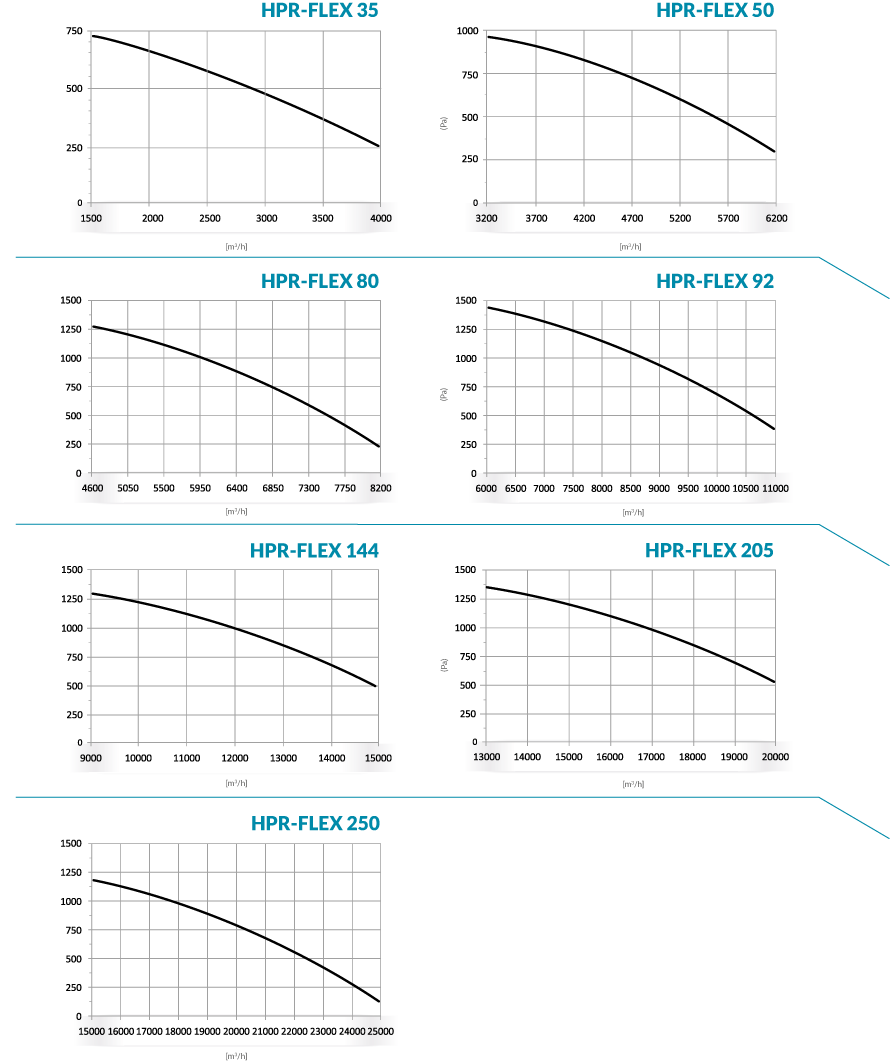

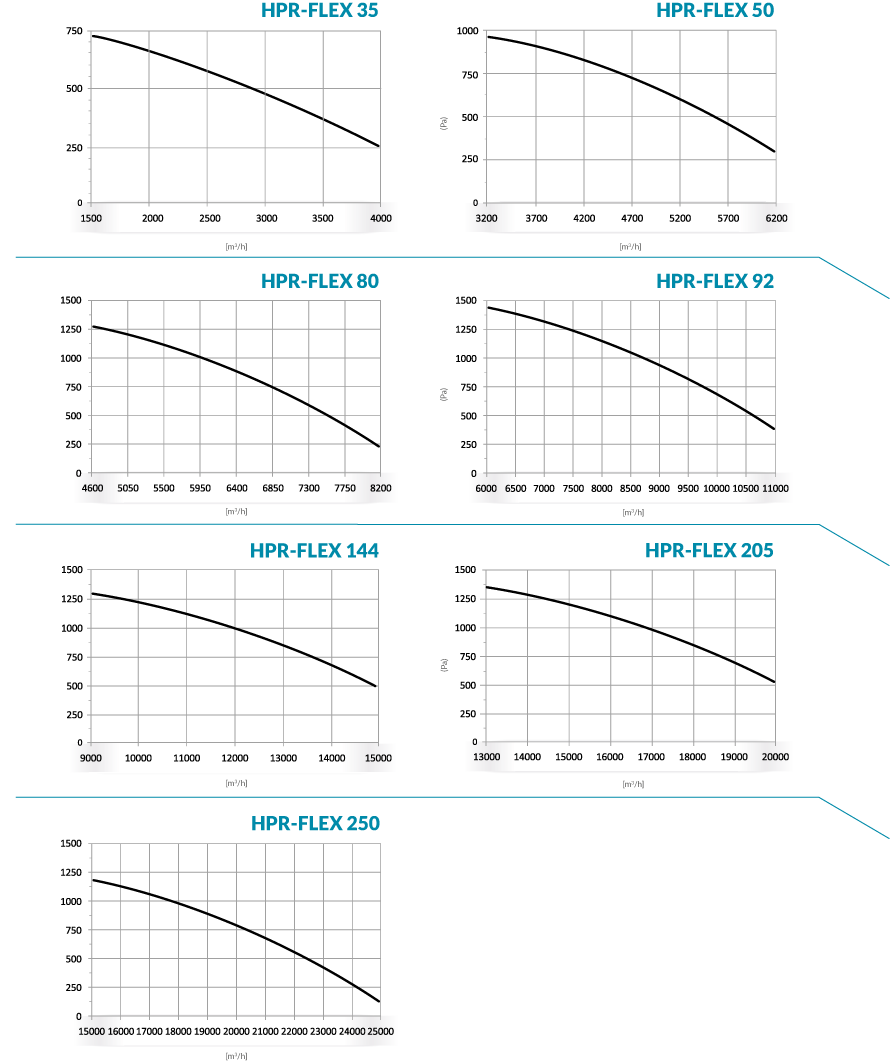

The graphs provide an indication of the useful static pressure (Pa) as the airflow [m 3/h] [m3/h]supplied by the base inlet unit varies. Consult the technical bulletin to check the specific data of the unit’s aeraulic performance.

table shows the sound power values (SWL) in octave band and the related results; the sound pressure values (SPL) at 1m, 5m and 10m in supply, in return and outside of the unit are also highlighted, under ducted unit conditions.

table shows the sound power values (SWL) in octave band and the related results; the sound pressure values (SPL) at 1m, 5m and 10m in supply, in return and outside of the unit are also highlighted, under ducted unit conditions.