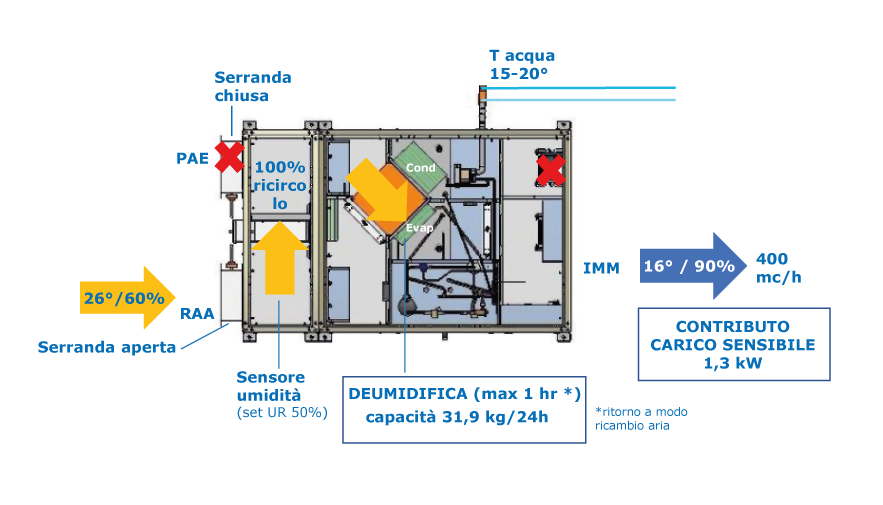

Outside air introduced into the building is cooler if compared to the return air, thus contributing to reduce the colling sensitive load.

During the dehumidifying process the unit produces warm water (with a temperature of 45°C) for free use (e.g. boiler DHW).

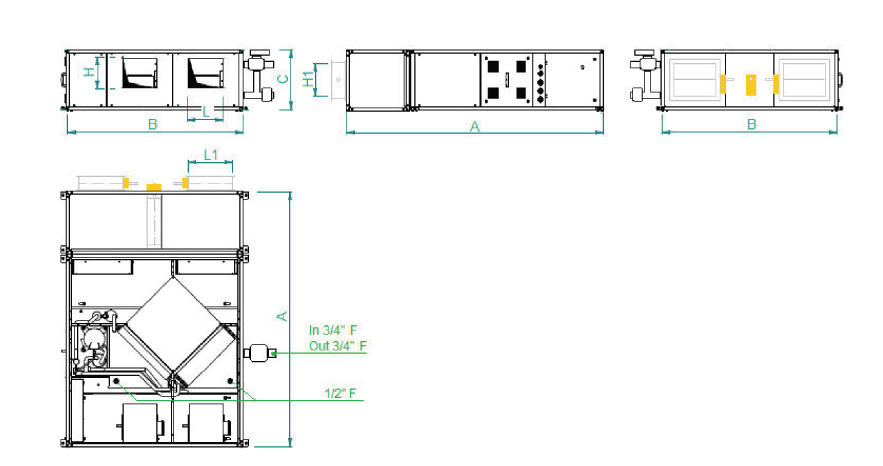

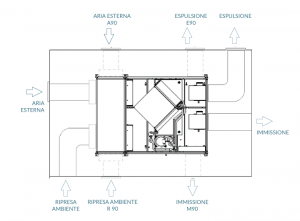

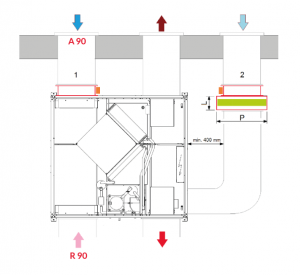

It is possible to adapt the intake and exhaust dampers to the system according to the configurations shown below, even when the unit is already installed.

EXTERNAL BY-PASS SYSTEM BPL

Set of components installed (by the customer) outside the unit, provided only if the configuration of the same is with M90 and E90 fans, capable of creating, controlled by the on-board electronics, an additional circuit external air (external free-cooling air) in direct communication with the supply fan.

The Kit consists of:

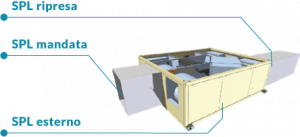

With reference to the nominal operating conditions, the following table shows the sound power values (SWL) in octave band and the related results; the sound pressure values (SPL) at 1m, 5m and 10m in supply, in return and outside of the unit are also highlighted, under ducted unit conditions.

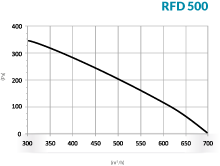

The graphs provide an indication of the useful static pressure (P a) as the airflow [m3/h] supplied by the base inlet unit varies. Consult the technical bulletin to check the specific data of the unit’s aeraulic performance.

Via Paradiso, 33

Meledo di Sarego (VI) - 36040, ITALIA

Phone: +39 0444 821279

Fax: + 39 0444 820323

E-Mail: [email protected]