(A) input temperature ≤ 24°C; balanced air flow rates

(B) input temperature ≥ 22°C; balanced air flow rates

(1) outdoor air at -5°C 80% RH, ambient air at 20°C 50% RH; nominal air flow rate

(2) outdoor air at 32° C 50% RH, ambient air at 26°C 50% RH; nominal air flow rate

(3) with ventilation regulation signals and heat pump at the maximum permissible value

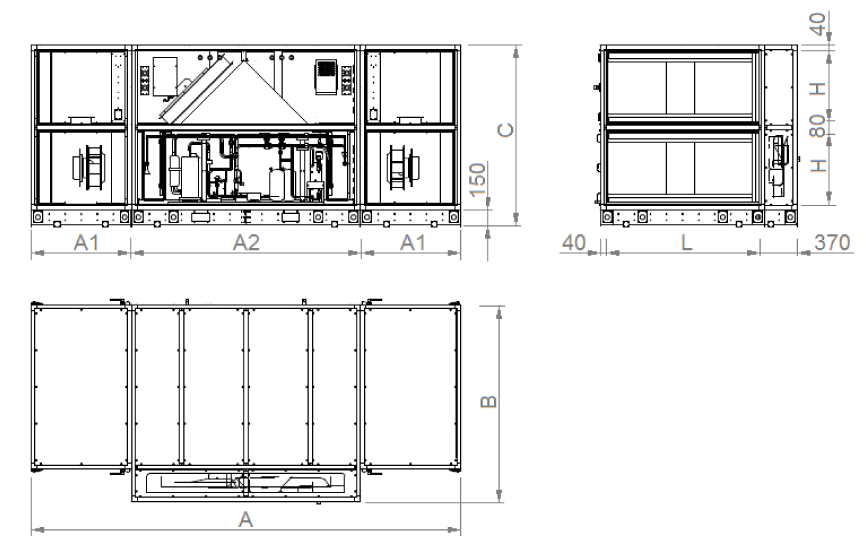

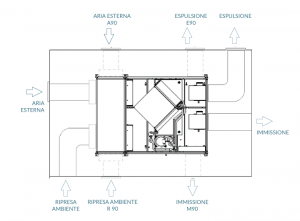

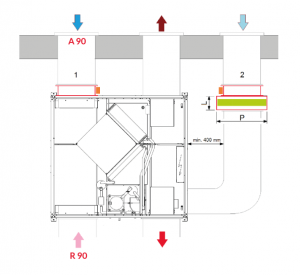

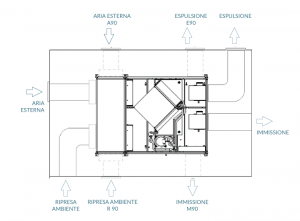

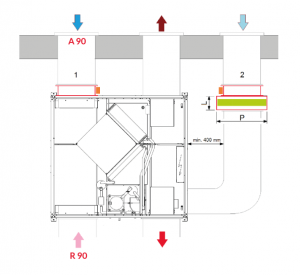

For each size, it is possible to adapt the fresh air and exhaust intakes to the system according to the configurations illustrated in the figure, even with unit already installed.

To change the position of the intakes simply exchange the filter panels with the corresponding panels.

The M90 configuration must necessarily be specified on the order as it involves exchanging the positions between the supply fan and the electrical panel, this operation that is not possible with the unit is already installed.

BPL EXTERNAL BY-PASS SYSTEM

A set of components installed (by the customer) outside the unit, required if the configuration of the unit is with M90 and E90 fans, able to create, commanded by the on-board electronics, an additional circuit of external air (free-cooling outdoor air) in direct communication with the supply fan.

This kit consists of:

- Servomotor damper on the fresh air (1)

- Ducted module on free-cooling air duct with servomotor (opposed to the previous one) and an high efficiency filter extractable from below.

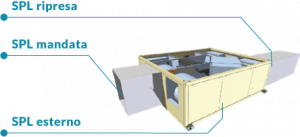

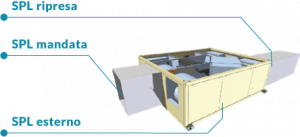

The table shows the sound power values (SWL) in octave band and the related results; the sound pressure values (SPL) at 1m, 5m and 10m in supply, in return and outside of the unit are also highlighted, under ducted unit conditions.