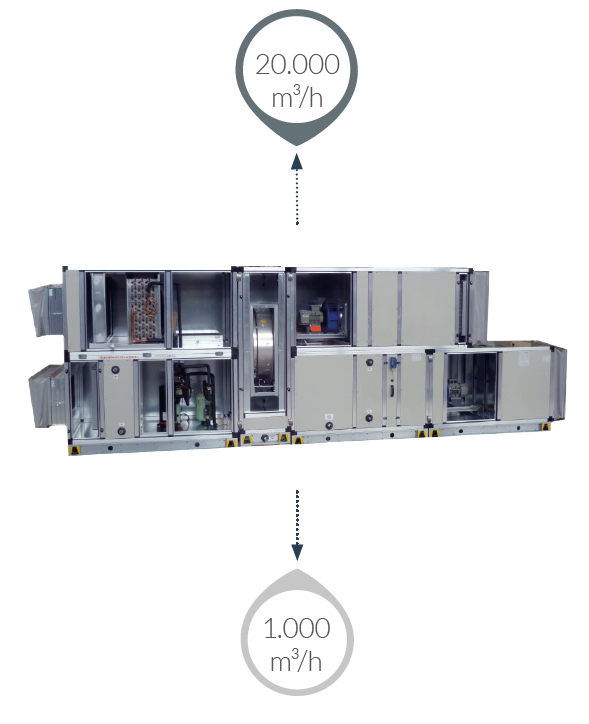

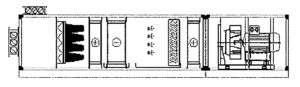

Single-flow AHU with P.A.E. damper, Coarse 50% + ePM1 50% filters, heating coil, steam humidification coil, fan:

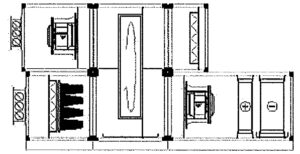

- Single-flow AHU with mixing chamber (recirculation and P.A.E.), Coarse 50% + ePM1 50% filters, heating coil, cooling coil, steam humidification, post-heating coil, plug-fan.

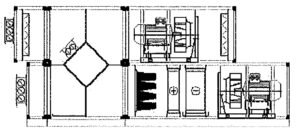

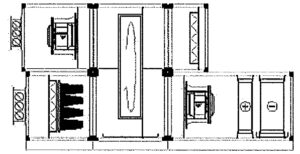

- AHU with plate heat recovery system (cross-flow or counter-current), supply and return plug fans, Coarse 50% or ePM10 50% return and Coarse 50% + ePM1 50% supply filtration, coil heating, cooling coil.

- AHU with rotary heat recovery system, EC type supply and return plug fans with 0-10v control and brushless motor, Coarse 50% or ePM10 50% return and Coarse 50% + ePM1 50% return filtration, heating coil, cooling coil.

- Use of the best components available on the market in terms of fans, filtration, heat recuperators (plate and rotary) and regulation