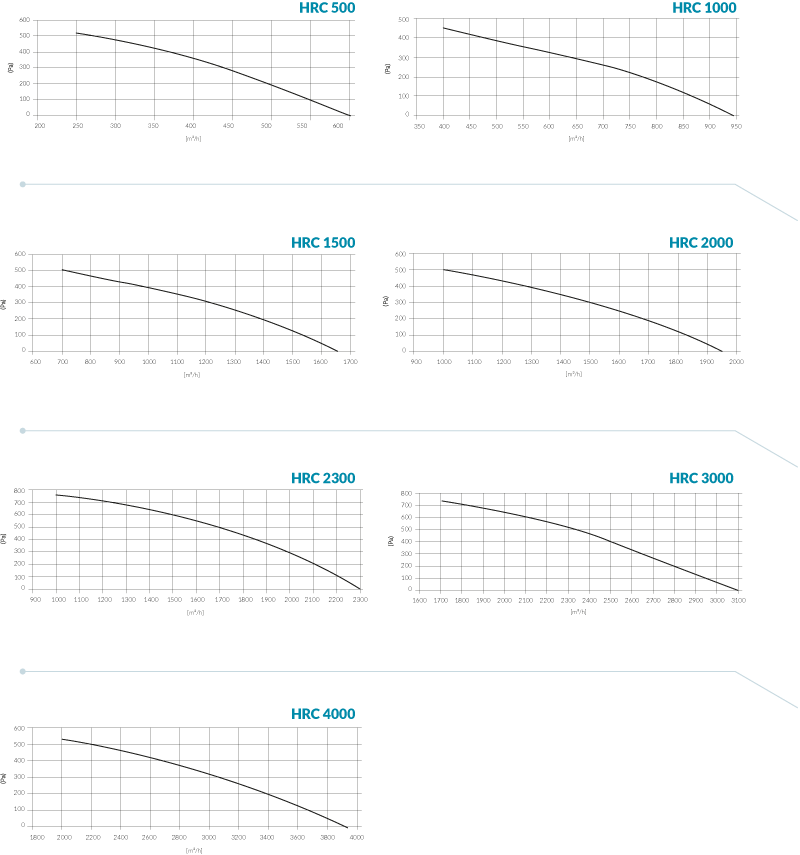

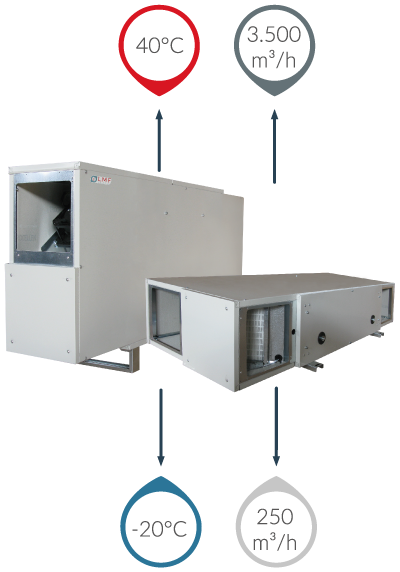

(1) referred to nominal flow rate

(2) inlet air at 28°C/60%UR; water in/out 7°/12°C

(3) inlet air at 13°C/; water in/out 45°/40°C

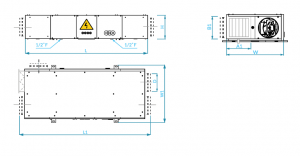

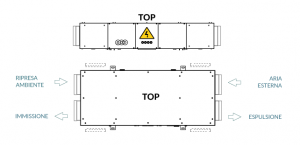

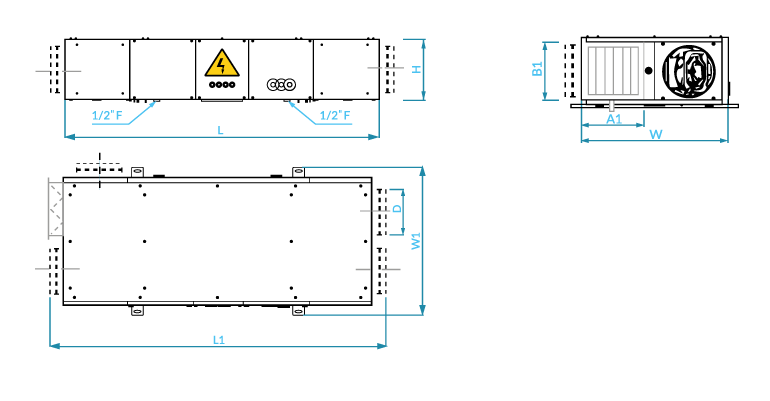

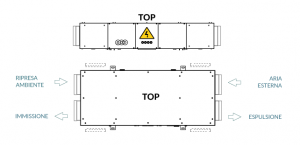

Two air flow configurations are available, a “right” and a “left” one, both referring to the view of the electrical panel:

With the first, the inlet fan (and therefore the aeraulic connection for the supply to the rooms to be treated) is located to the right of the electrical panel. All other air intakes are therefore uniquely determined.

With the second, the inlet fan (and therefore the aeraulic connection for the supply to the rooms to be treated) is located to the left of the electrical panel. All other air intakes are therefore uniquely determined

All air intakes can still be adjusted by 90° by moving the side end closing panels, even in the installation site. The KTV conversion kit does not change the aeraulic structure defined above.

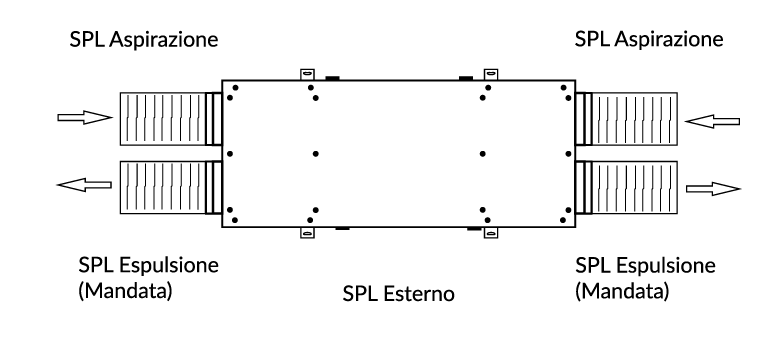

With reference to the nominal operating conditions and balanced flow rates, the following table shows the sound power values (SWL) in octave and total bands.

The sound pressure levels (SPL) at 1m, 5m and 10m in supply/exhaust, outdoor air/return and outside the unit, in ducted unit conditions are also indicated.

Two air flow configurations are available, a “right” and a “left” one, both referring to the view of the electrical panel:

With the first, the inlet fan (and therefore the aeraulic connection for the supply to the rooms to be treated) is located to the right of the electrical panel. All other air intakes are therefore uniquely determined.

Two air flow configurations are available, a “right” and a “left” one, both referring to the view of the electrical panel:

With the first, the inlet fan (and therefore the aeraulic connection for the supply to the rooms to be treated) is located to the right of the electrical panel. All other air intakes are therefore uniquely determined.

With the second, the inlet fan (and therefore the aeraulic connection for the supply to the rooms to be treated) is located to the left of the electrical panel. All other air intakes are therefore uniquely determined

All air intakes can still be adjusted by 90° by moving the side end closing panels, even in the installation site. The KTV conversion kit does not change the aeraulic structure defined above.

With reference to the nominal operating conditions and balanced flow rates, the following table shows the sound power values (SWL) in octave and total bands.

The sound pressure levels (SPL) at 1m, 5m and 10m in supply/exhaust, outdoor air/return and outside the unit, in ducted unit conditions are also indicated.

With the second, the inlet fan (and therefore the aeraulic connection for the supply to the rooms to be treated) is located to the left of the electrical panel. All other air intakes are therefore uniquely determined

All air intakes can still be adjusted by 90° by moving the side end closing panels, even in the installation site. The KTV conversion kit does not change the aeraulic structure defined above.

With reference to the nominal operating conditions and balanced flow rates, the following table shows the sound power values (SWL) in octave and total bands.

The sound pressure levels (SPL) at 1m, 5m and 10m in supply/exhaust, outdoor air/return and outside the unit, in ducted unit conditions are also indicated.